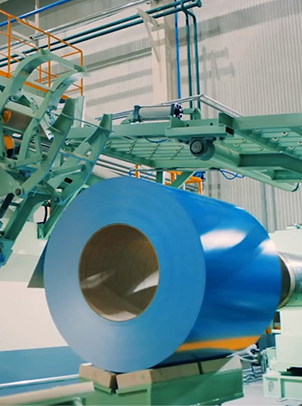

Product Overview Premium quality color coated steel coils for long-lasting durability and vibrant aesthetics. Ideal for roofing, wall cladding, and industrial applications. Product Specifications Lines: Pre-painted Steel Sheet Thickness (mm): TC 0.25-1.0 Width (mm): 700-1250 Coil weight (MT): 3.0-8.0 Zinc coating: 20-160g/㎡ Painting: Top 15-30μm Back 7-20μm Substrate: Al-Zn coated steel sheets; AZM steel sheets Painting system: PE、S-PE、SMP、HDP、S-DP、PVDF Strength: G250/G280/G300/G320/G345/G350/G550 MOQ: 16 tons per size Payment term: T/T; L/C at sight Quality Assurance product certification Application Construction industry : Factory buildings, agricultural warehouses, prefabricated residential components, corrugated roofs, walls, rainwater pipes, balconies, kiosks, rolling shutters, etc. Electrical appliances : Refrigerators, washing machines, switch cabinets, instrument cabinets, air conditioners, microwave ovens, bread makers, etc. Home furnishings : Radiators, lamp shades, wardrobes, tables, beds, changing boxes, bookshelves, etc. Transportation industry : Interior panels of automobiles and trains, partitions, containers, isolation barriers, bulkhead panels of ships, etc. Others : Whiteboards for writing, garbage bins, billboards, clocks, typewriters, instrument panels, weighing scales, photographic equipment, etc. Production Process The annual designed production capacity of Shinmade's color-coated production line is 150,000 tons, and it has multi-faceted advantages. 1、The Siemens electrical control system ensures more stable production. 2、Equipped with a weld seam or riveted joint tracking system, the production operation is smoother. 3、The coating machine is equipped with a pressure sensor, enabling more precise control of the product's paint film. 4、Three-roll coating is applied on the front side, making the thickness of the paint film on the product surface more uniform and the paint surface texture more aesthetically pleasing. 5、The extra-long oven allows for precise temperature control, ensuring more complete curing and cross-linking of the paint. 6、With the installation of a tension leveler, the shape of the product panels is better guaranteed. FAQ Q: What types of steel coils do you supply? We offer a wide range of coils including GL, PPGL, and CR. Q: Can I customize the coil specifications ? Yes. We support full customization of thickness, width, coating weight, paint color, and surface finish based on your specific requirements. Q: What is the minimum order quantity ? Our standard MOQ is usually 16 tons per specification. Q: Do you provide samples before placing bulk orders? Yes. We can provide free samples. Q: How long can your painted coils last in outdoor conditions? Our PPGL coils can last 20–40 years depending on environmental exposure. Q: What industries use your steel coils? Our coils are used in construction, automotive parts, appliances, solar frames, storage tanks, and more. Click to learn more: company profile environmental friendly honors and qualifications scientific research and innovation

Product Overview Galvalume steel sheets have a coating composition of 55% aluminum, 43.5% zinc, and 1.5% silicon. They exhibit excellent resistance to atmospheric corrosion, with their corrosion resistance being 2-4 times that of galvanized steel sheets at the same coating thickness. Meanwhile, they also possess the high-temperature corrosion resistance of aluminum sheets. Product Specifications Lines: Galvalume Steel Coil Thickness (mm): TC 0.2-1.2 Width (mm): 800-1260 Coil weight (MT): 3.0-8.0 Zinc coating: 30-220 g/㎡ Painting: 0.5-1.5μm Coating Composition: 55% Aluminum - 43.5% Zinc - 1.5% Silicon Strength: G250/G280/G300/G350/G550/ DX51D/DX52D MOQ: 32 tons per size Payment term: T/T; L/C at sight Quality Assurance Product Advantages Small dendrites space distance With unique formula of the coating and control of coating thickness, the dendrite spacing of Shinmade galvalume steel is 10-15μm under electron microscopy, and the corrosion resistance of the product is excellent. Coating cross-sectional structure - optical microstructure The coating structure of Shinmade’s products is a staggered skeleton, which has good density and can prevent the intrusion of rainwater and other corrosive media, and that is why the product has good corrosion resistance. If the coating structure is bamboo-like, which means the coating layer is not dense enough and the corrosion resistance can be poor. Small-sized and uniform spangle The stability of crystallization determines the size and uniformity of spangles. The spangles are precisely controlled under the combined effects of the steel strip temperature, zinc liquid temperature, surface roughness, post-plating cooling, and special coating formula. The diameter of the spangle of Shinmade's galvalume is controlled between 0.5-3mm, which means the spangles are small-sized and uniform, and the appearance effect is more stable. Chromate/Passivation+AFP We adopt double-coating and baking process for post-treatment, which means we first to passivate, dry and cool the sheets, next to apply AFP coating on the sheets and dry and cool. The AFP film is thicker and cured better, so the processing lubricity is relatively better. Applications Construction industry: Roofs, exterior walls, color - coated substrates, garage doors, fences, shutters, ventilation ducts of civil and industrial buildings, etc. Industrial instrumentation: Electric control cabinets, industrial freezers, vending machines, etc. Home appliance industry: Washing machines, refrigerators, televisions, air conditioners, ovens, outer covers of ventilation systems, explosion - proof strip steel, solar water heaters, electrical components, etc. Other industries: Automobile mufflers, heat shields for exhaust pipes and catalytic converters, parts at the bottom of automobile bodies, highway signs, car horns, small hardware, etc. Production Lines Shinmade owns 2 galvalume production lines with an annual designed production capacity of 550,000 tons. 1、Siemens electrical control system 2、German EMG correction CPC/EPC system 3、9-stage cleaning system 4、Ultra-long horizontal annealing furnace 5、Advanced air knife system 6、Online X-Ray coating thickness measurement gauge 7、Wet finishing design (skin- pass strength 5000kN) 8、Double-bending and tension-leveling ( wet leveling and straightening )process 9、Double coating (passivate and AFP) and baking configuration FAQ Q: What types of steel coils do you supply? We offer a wide range of coils including GL, PPGL, and CR. Q: Can I customize the coil specifications ? Yes. We support full customization of thickness, width, coating weight, paint color, and surface finish based on your specific requirements. Q: What is the minimum order quantity ? Our standard MOQ is usually 32 tons per specification. Q: What coating and painting systems do you offer? We provide Al-Zn coatings with various paint systems including PE, SMP, HDP, and PVDF. The choice depends on your intended application. Q: Do you provide samples before placing bulk orders? Yes. We can provide free samples. Q: How long can your painted coils last in outdoor conditions? Our GL coils can last 20–30 years depending on environmental exposure. Click to learn more: company profile environmental friendly honors and qualifications scientific research and innovation

Product Overview Zinc - aluminum - magnesium products are usually classified into three categories according to the aluminum content in the coating: low - aluminum products, medium - aluminum products, and high - aluminum products.They are characterized by high corrosion resistance and high cut - edge protection. Product Specifications Item: Details Coating Composition: 53% Aluminum - 43.4% Zinc - 1.6% Silicon - 2% Mg Coating Thickness: AM60 - AM200 Product Thickness: 0.15 - 1.60 mm Product Width: 700 - 1260 mm Product Advantages Mechanism of Corrosion Resistance A large number of experiments verify that AZM products have excellent corrosion resistance and are the trend in the construction field. The reasons are as follows: · Zinc provides sacrificial protection; · Aluminum provides passivation protection; · Magnesium,together with zinc and aluminum are to reduce the consumption rate of the coating; · Mg2Si formed below the coating provides barrier protection inside the coating. Ten-week cyclic Q-Fog test (Q-fog CCT) After 10 weeks of cyclic corrosion comparison experiments, there was no obvious change on the surface of the Al-Zn-Mg samples (AM150 gsm and AM100 gsm), a little red rust appeared on the surface of the galvalume sample (AZ150 gsm), and a large area of rust appeared on the surface of the galvalume sample (AZ100 gsm). Eleven-month marine environment exposure After 11 months of marine environment exposure experiments, there was no obvious change on the surface of the PPAM (AM50 gsm) sample, while salt frost appeared locally on the surface of the PPGL (AZ50 gsm)sample. Fourteen-month outdoor acid rain environment exposure After 14 months of exposure to outdoor acid rain environment, there was no obvious change on the surface of the Al-Zn-Mg samples (AM150 gsm and AM100 gsm), but the surface of the galvalume sample (AZ150 gsm) began to rust, and the surface of the galvalume sample (AZ100 gsm) had been rusted over a large area. FAQ Q: Can I customize the coil specifications ? Yes. We support full customization of thickness, width, coating weight, paint color, and surface finish based on your specific requirements. Q: What is the minimum order quantity ? Our standard MOQ is usually 32 tons per specification. Q: Do you provide samples before placing bulk orders? Yes. We can provide free samples. Q: What industries use your steel coils? Our coils are used in construction, automotive parts, appliances, solar frames, storage tanks, and more. Click to learn more: company profile environmental friendly honors and qualifications scientific research and innovation

Product Overview Cold-rolled steel sheets have good properties. With high flatness, gloss and bright surface,cold-rolled steel sheets are easier to be coated and processed. Cold-rolled steel sheets are mainly used in the packaging industry and used as the substrates of galvanized steel sheets, galvalume steel sheets and Zn-Al-Mg alloy coated sheets. Product Specifications Lines: Cold-rolled Steel Sheet Thickness (mm): 0.06-2.0 mm Width (mm): 750-1320mm ID: 508mm Max OD: 2000mm Max coil weight: 26000kg Annual capacity: 1300000 tons Production Lines Shinmade has 7 cold-rolled production lines with an annual capacity of 1.4 million tons. The production specification ranges from 600-1300mm in width, 0.06-2.0mm in thickness with a tolerance of ±0.01mm. The production lines are equipped with Fuzzy shape control systems, the shape measuring rollers made by ABB in Switzerland, R-700 PLC systems developed by Hitachi, and advanced PCS7 thickness control systems of Siemens. Product Packaging FAQ Q: Can I customize the coil specifications ? Yes. We support full customization of thickness, width, coating weight, paint color, and surface finish based on your specific requirements. Q: What is the minimum order quantity ? Our standard MOQ is usually 32 tons per specification. Q: Do you provide samples before placing bulk orders? Yes. We can provide free samples. Q: What industries use your steel coils? Our coils are used in construction, automotive parts, appliances, solar frames, storage tanks, and more. Click to learn more: company profile environmental friendly honors and qualifications scientific research and innovation

Shinmade products can be used in industrial plants, gymnasiums, airports, stations, indoor partitions, warehouses, elevators, metal curtain walls and other places, and are exported to more than 20 countries and regions.

On December 13, 2025, the 2nd Session of the 4th Council and Member Congress of Beijing Steel Structure Industry Association, hosted by Shinmade, was held in Beijing. Concurrent with this congress wer...

Read moreRecently, at the site of the China International Import Expo (CIIE) in Shanghai, Shandong Shinmade Technology Materials Co., Ltd. and Primetals Technologies, a global leader in metallurgical technolog...

Read moreGrateful for the encounter, the excitement continues The several-day-long 138th Canton Fair has successfully concluded in Guangzhou! At this grand event gathering global business opportu...

Read moreRecently, upon authentication by the Shanghai Metal Structure Industry Association,Shandong Shinmade Material Tech Co. has been awarded the title of "2024 Shanghai Metal Structure Industry Integ...

Read moreFrom October 13th to 15th, the 9th Member Representative Congress & 2025 China Steel Structure Congress, hosted by the China Steel Structure Association, was held in Nanning, Guangxi. As an annual...

Read moreOn August 15th, the 19th China Metal Plate Industry Chain Annual Conference 2025 was held in Zhengzhou. As a domestic high-end metal plate manufacturer, Shinmade deeply participated in this gra...

Read moreIt is known from Tianjin Custom that 544 batches of iron ore were imported at Tianjin port during the first half of 2020, totally reaching 37.859 million tons, increased by 20.6% and 13.6% respectivel...

Read moreWith the EU recovering from Covid-19, it plans to modify its import restrictions on steel to deter any unhealthy market situation. The proposal will modify the EU import restrictions published two yea...

Read moreEmail :

info@shinmade.comScan To Wechat