Call Us Now

+86-543-2120695

In June 2019, our company successfully developed a 0.06mm ultra-thin steel strip-steel foil, becoming the first in the industry to successfully develop this product, which also improved our company's market competitiveness.

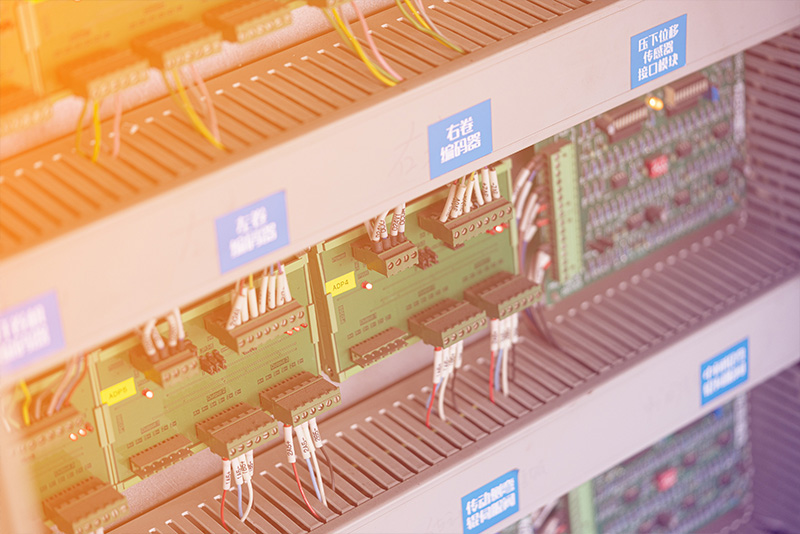

AGC system transformation

|

The AGC system transformation of the rolling mill can effectively improve the stability of the rolling system, solve the rolling gap issue and the thickness fluctuation issue. By AGC transformation, the rolling mill capacity increased due to the improvement of the yielding rate. |

|

|

|

|

|

|

R&D of 0.115*750mm CRC

The main issue is on edge quality and this research project effectively solves the after-rolling crack problem, thus improved our edge condition.

R&D

| New technique of 99.23% transformation of 1380 rolling mills |

Technique of 94.18% transformation of cold rolled coils |

| Technology reserach of disposal of waste emulsion |

Technology research on washing tower improvement of pickling lines |

|

Technology research on roller beraing of six-bar mills |

System cooling & Water Demineralization disposal |

|

Testing on content of iron ions in emulsion |

Testing on content of chlorine ions in emulsion |

|

Improvement of 1200 mills roller system |

Acid mist recovery and purification technology of pickling lines |

|

Technology improvement of extruding rollers encoder of pickling lines |

Transformation of 1380 supporting rollers to 1200 supporting rollers |

|

Grinding technique of lining bearings of 20-bar mills |

Lowering of acid mist efflux of acid regeneration |

|

Disposal of waste emulsion during cold rolling process |

Research of roller bearing of 6-bar mills |

|

New technique of CPC centering and leveling of rolling mills |

Research of automatic disassembly and installation of grinding bearings |

|

Automatic cleaning facilities of grinding bearings |

Research on 9-bar straightener structure of pickling lines |

|

Research of roller structure of re-coiling mills |

Technique Research of structure of deoiling flattening rollers |

|

Research of CRC 0.115mm*750mm |

Research of handling facilities of waste clay minimization |

|

New Technique Research of six-bar roller straightener |

New Technique Research of vipor recycling utilization during pickling lines |

|

New Technique Research of universal coupling of 3# rolling mills |

New Technique Research of upgrading of six-bar supporting roller from 60-150 mm |

|

New Technique Research of CPC deviation an sppeding up in pickling lines |

Research of magnetic filter cleaning facilities on oil saving and emission lowering |

|

Research of cooling and recycling of iron fines and waste water during acid-regeneration |

eTQM system development of CRC based on intellectual and informative technology |

|

Research of wireless monitoring and pre-warning system on rollers bearing temperatures |

|

Scan To Wechat