Call Us Now

+86 18706432618

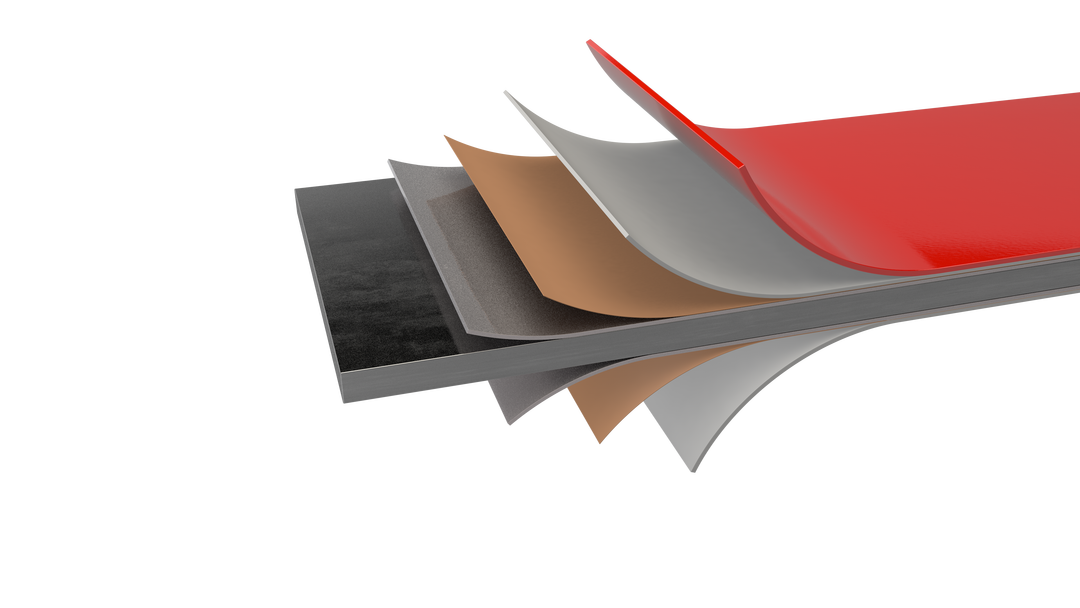

After more than a year of construction and close preparations, Shinmade color-coated panels are about to be put into production. Among the many advantages of the product, chrome-free is one of the highlights. It is committed to providing customers with green and environmentally friendly color coating products, leading industrial development with innovative technology, and helping environmental protection.

Chromium Hazards and Chromium-Free Challenges

For a long time, the color-coated boards of exterior building materials are mostly coated with a passivation film and primer containing hexavalent chromium on the surface of the substrate to achieve good corrosion resistance and adhesion. However, since hexavalent chromium is an environmental load substance, it has extremely serious harm to the environment and the human body.

Chromium pollution exists in the air, water, food, and soil. Chromium in the environment can be enriched in plants and animals through the food chain, and eventually enter the human body, endangering human health. Some hexavalent chromium compounds have been found to cause cancer in the body.

Shinmade actively responds to the national environmental protection policy, has determined the direction of chrome-free before the official implementation of the new national standard GB 30981-2020, and insists on using chrome-free primers in the production of color-coated sheets. How to pursue environmental protection without affecting corrosion resistance has become a key problem in the process of product development.

Color-coated panels with new chrome-free primer

By joining hands with Nippon Paint, an internationally renowned paint manufacturer, Shinmade has mastered a breakthrough technology that satisfies both chrome-free and corrosion resistance.

After testing, the content of VOC and harmful substances in the new chrome-free primer used not only meets but is far lower than the latest national standard GB 30981-2020. Under the same laboratory conditions, the corrosion resistance of the product and the adhesion to the substrate are comparable to those of the chrome primer. Combining different types of substrates and topcoats of various systems, various high-performance color-coated boards have been developed, which can be used in industrial manufacturing plants, public buildings and other fields.

In addition to the use of safer and more sustainable chrome-free primers, the passivation treatment of Shinmade color-coated substrates adopts a vertical roller coating process, which can greatly improve the uniformity of the treated film and accurately control the coating amount, not only It can achieve better coating performance, and can also reduce the leakage and discharge of toxic treatment liquid, which is more beneficial to human health, environmental protection and sustainable development.

Continue to practice the concept of green development

In the process of development, Shinmade implements the concept of recycling and green development strictly implements environmental quality requirements, and provides customers with sustainable green and environmentally friendly steel solutions.

The exhaust air is absorbed by a secondary absorption tower, and the emission index is far better than the national standard; the new material corrosion inhibitor, reducing the annual carbon dioxide emission is equivalent to planting 518,840 trees, equivalent to reducing the annual exhaust emission of 1,365 cars.

The wastewater generated in the production process adopts a new advanced oxidation process, uses clean auxiliary materials to replace the original process materials, implements a clean operation, and reduces the amount of hazardous waste by 90% annually. At the same time, the indicators after wastewater treatment are far better than the industry standard.

Scan To Wechat